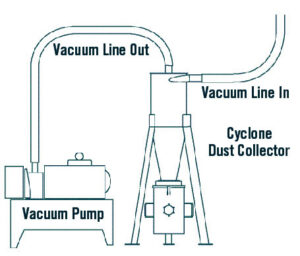

Cyclone dust collectors are free standing and may be located anywhere between the pump filter and the conveying system. Their primary purpose is to protect a system vacuum pump from damage by carryover dust and fines. Usually, there is one cyclone per system pump.

A good cyclone dust collector will pay for itself many times over. If designed and built properly, the cyclonic action will it will remove up to 99% of carry over fines that are drawn towards, and can damage, the central pump in a vacuum conveying system.

There are no moving parts and no bulky canister filters to clean. The fines can be easily emptied from a sealed dust collection pan under the cyclone.

Cyclone filters are sized to match the conveying line diameter and the air volume produced by the system vacuum pump.

Options:

- Drum dump – includes a dust sock that fits over a 30 gal. drum for fines collection

Features to look for:

- Sight glass on collection pan – allows visual confirmation of when to empty

- Quick release clamps on collection pan – for easy removal

- No parts or canister filters to replace

Notes:

- Not all cyclone dust collectors are created equal – be sure that it is rated to remove 99% of dust and fines.

- There are also Filter Dust Collectors. Some require that bulky cannister filters be cleaned regularly while others rely on a type of filter that traps the dust, then releases it into a collection bin.

Ask the Expert