Decoding Resin Moisture Analyzers: Which Method Is Right for You?

Hey there, plastics processors! Ever find yourself scratching your head, trying to figure out the best way to measure resin moisture with so many different moisture analyzers on the market? In the world of plastics processing where precision is king and time is money, choosing the right moisture analyzer is no small feat. Today, let’s cut through the fog and lay out the land with the popular moisture analysis methods: Loss in Weight, Karl Fischer Titration, Relative Humidity Sensor, and the Calcium Hydride method. Ready to roll up our sleeves and demystify these technologies? Let’s jump right in!

Loss in Weight: The No-Frills, Broad Approach

Now, let’s talk about the old Loss in Weight method, a classic in our industry. At the core of this method lies a simple yet profound principle that dates back to the early days of industrial moisture analysis. Brands like Sartorius and Ohaus have built upon this foundation, offering models that embrace its straightforward approach: weigh the resin, heat to evaporate moisture, and weigh it again. The difference? That’s what this method calls the moisture content: the weight before and after heating the sample. But, and it’s a big but, this method doesn’t discriminate between water and other volatile substances that might evaporate alongside it. It’s like a fisherman who can’t tell a salmon from a trout. It can’t tell water from all the other stuff that might also take off when heated.

Let me paint you a picture. You’re whipping up a big pot of stew. You start with everything in the pot (that’s your resin). As it cooks (the heating process), some of that liquid evaporates. What you’re left with is a thicker, richer stew (that’s your post-cooking weight). This is like our Loss in Weight method – a way of measuring by observing the changes before and after a process. The problem is that it’s like trying to identify individual ingredients just by tasting the final stew. It’s great if you’re in an industry that’s not fussy about the specifics, especially since it’s so cost effective…but in plastics processing, where exact trace moisture amounts are vital for ensuring product integrity and quality, this approach just doesn’t cut the mustard.

- Accuracy: Decent for an overall picture, but it’s definitely a blunt tool.

- Set-up Time: Fast, about 3 minutes.

- Ease-of-Use: Intuitive, no training needed.

- Mobility: Mobile. Plug it in and use it wherever needed.

- Price: All over the map, from $700 – $15,000.

Karl Fischer Titration: The Gold Standard in Accuracy

Next up, is the Karl Fischer Titration. This method is the epitome of precision in moisture analysis. Invented back in the ’30s by the man Karl Fischer himself, it involves a delicate chemical reaction specifically targeted at water molecules. Models like Mettler Toledo’s Karl Fischer Titrators are the standard-bearers of this method. This is not just a moisture measurement; it’s the Sherlock Holmes of moisture analysis in plastics processing, isolating and quantifying water content with unparalleled accuracy.

Here’s how it works: your plastic resin is essentially put under a microscope, chemically speaking. A reagent is introduced to the sample, which reacts specifically and only with water. As this reaction unfolds, the titration method meticulously measures how much reagent is consumed. It’s like measuring how much tea Sherlock drinks while solving a case – the more tea he drinks, the bigger the case. In titration, the amount of reagent used directly correlates to the exact amount of moisture present in the sample. It’s not fooled by other volatiles or substances that might be off-gassing alongside water; it’s a method with a one-track mind, solely dedicated to detecting water molecules.

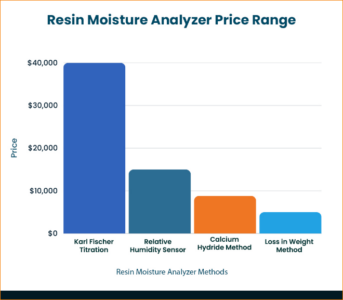

The only problem is that Karl Fischer titration systems can be a bit like a high-maintenance sports car – they deliver performance but come with complexity and a hefty price tag (check out the graph below to see for yourself). These systems are a complicated symphony of chemical interactions that require a thorough understanding and an intricate, time-consuming setup. And it’s this complexity that’s historically placed titration equipment more comfortably in the realm of specialized laboratories rather than the dynamic floor of a processing operation.

- Accuracy: Unparalleled, a chemical sleuth for water.

- Set-up Time: Takes a while, about 25-30 minutes.

- Ease-of-Use: Demands expertise and specialized training.

- Mobility: Suited for the lab, not for the production line.

- Price: Definitely and investment. Between $20,000-$40,000.

The Relative Humidity Sensor Method: The Contemporary Approach

Now, onto the Relative Humidity Sensor method, a somewhat newer kid on the block, used in instruments like the Computrac and VaporPro. This one’s about measuring the moisture in the air around your sample, a nifty indirect way to get the job done.

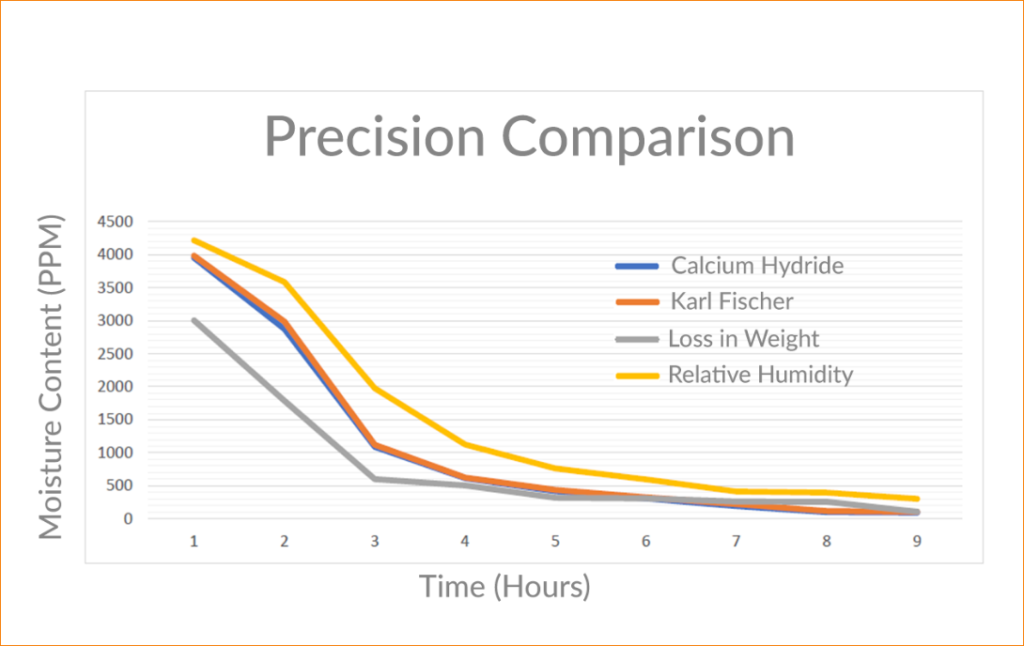

Think of it like a weatherman predicting rain. You’re not measuring every drop; you’re using tools to get the lay of the land. This sensor absorbs or releases water vapor depending on how moist or dry the air is. It’s a bit likesticking your hand out the window to see if you need an umbrella. It strikes a nice balance between the broad-brush approach of Loss in Weight and the precision and complexity of Karl Fischer Titration. And if you check out the graph below, you’ll see the set-up time is a bit quicker as well. It’s trusty like an old compass– won’t give you GPS-level detail, but it’ll point you in the right direction.

The Calcium Hydride Method: The Innovative Contender

And finally, let’s talk about the Calcium Hydride method, showcased in the Novatec HydroTracer HT3, powered by aboni. This is a novel approach in the moisture analysis landscape that leverages a chemical reaction between calcium hydride and the moisture in your sample, resulting in the production of hydrogen gas. The amount of this gas correlates directly to the moisture content, offering a unique and effective way to gauge moisture levels.

Think of it as a cool science experiment. You mix calcium hydride with your sample and watch the hydrogen gas bubble up. It’s a lively dance between two substances. The intensity and volume of the ‘dance’ (hydrogen gas production) directly relate to the moisture present. This method’s got the performance of a high-end sports car but is as user-friendly as your daily driver. Checkout the graph to see the results we got with ABS material – the HydroTracer’s accuracy stood toe-to-toe with the Karl Fischer Titration method.

The HydroTracer’s set up time is much faster than the other water-specific analyzers, even faster than the Loss in Weight method. And it’s about as easy to use as a single-serve coffee maker thanks to its pre-loaded polymer recipes, user-friendly software, and automatic report generation. Plus, with the HydroTracer’s innovative reagent test pads, adding the reagent is as simple as popping in a coffee pod. The HydroTracer is a precision moisture analyzer reimagined for the modern plastics processing operation.

- Accuracy: Rivals the precision of Karl Fischer.

- Set-up Time: Very fast, less than 2 minutes.

- Ease-of-Use: Extremely simple. No training or specialized knowledge required.

- Mobility: Rugged and mobile. Easily move it from the lab to the production line and back.

- Price: Much more affordable than the high-end titration and humidity methods.

Conclusion

As we wrap up our tour of moisture analysis methods, remember each one’s got its own charm and challenges. Whether you’re after simplicity and affordability or the crème de la crème of precision, there’s a tool out there for your needs. And if you’re leaning toward a method that blends top-notch accuracy with user-friendliness and a price that won’t make your wallet weep, well, the HydroTracer HT3 might just be your match made in heaven.

Curious for more information on resin moisture analysis and resin moisture management? Mosey on over to Novatec’s Resin Moisture Management page to learn more. The right tool not only makes your job easier but can turn good products into great ones. Here’s to smooth processing and top-notch results!

Ask the Expert