Overdrying Nylon: The Hidden Danger Sabotaging Your Parts

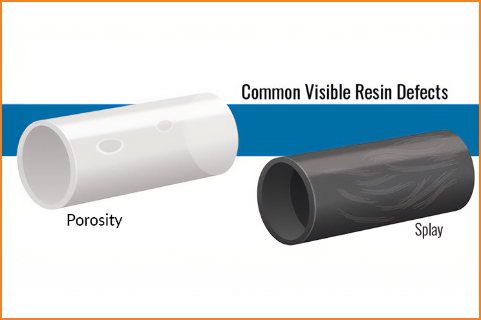

Alright, let’s get real about nylon. It’s a total rockstar in the resin world—tough, versatile, and reliable. But like any rockstar, it comes with some drama. And if you’ve ever had to deal with splay marks or porosity, you know exactly what I’m talking about.

Now, if you’ve been burned by underdrying, you might think, “I’ll just err on the side of caution to be safe!” But here’s the kicker: overcompensating can be just as bad, if not worse.

Overdrying doesn’t announce itself with visible defects. Instead, it quietly sabotages your parts at the molecular level, leaving them brittle and prone to failure.

Why Drying Blind is a Problem

Let’s face it—most processors don’t actually know how wet their nylon is when they start. And that’s a big problem. Nylon absorbs moisture from the air faster than your shoes in a puddle. So unless you just opened a fresh, perfectly sealed bag (and let’s be real—that’s rarely the case), you’re flying blind.

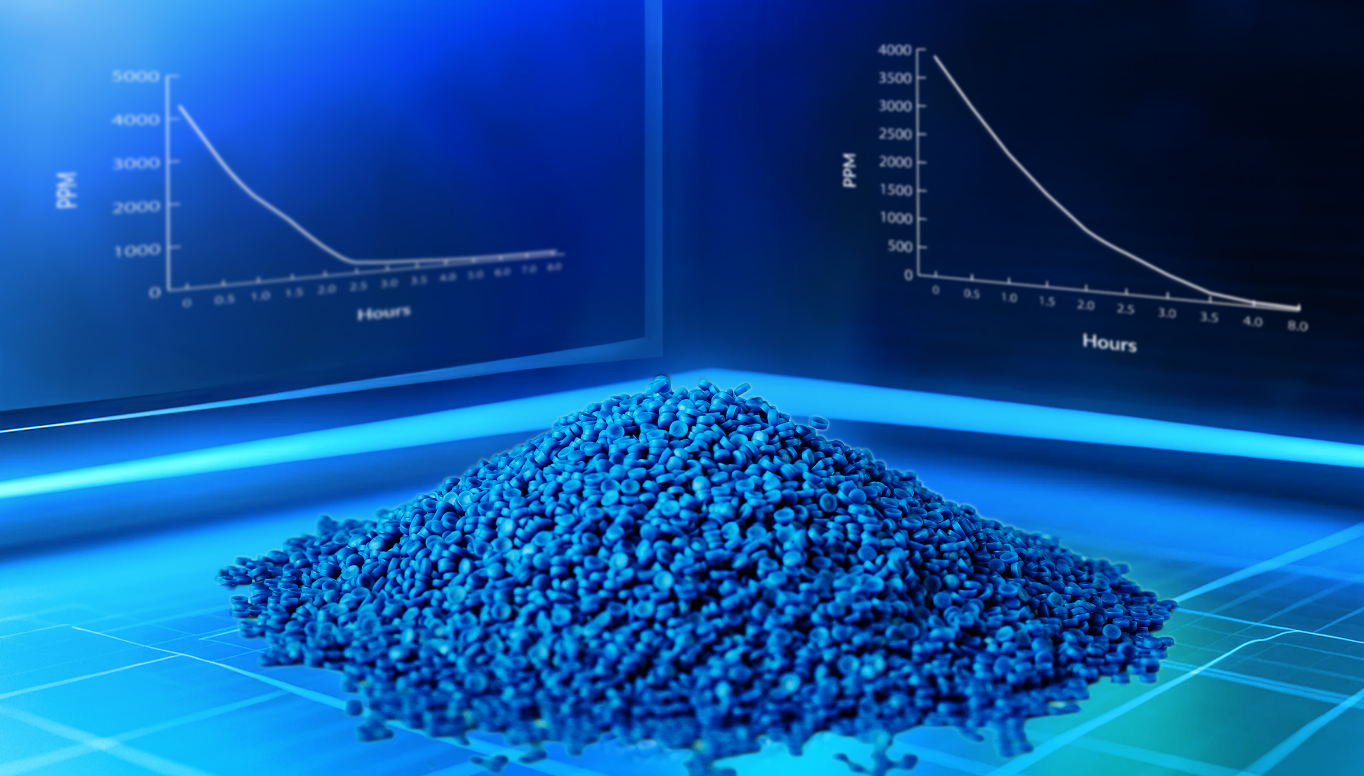

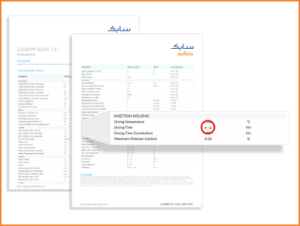

Resin supplier spec sheets say “dry for 4 to 6 hours”—but that assumes your nylon started with an average amount of moisture. What if your batch is drier than expected? What if it’s way wetter? The difference is huge. Some batches might only need 2 hours. Others might need more than 6. And since you have no idea where your nylon started, what do you do? You play it safe. You default to 6 hours, because why risk underdrying?

But here’s the problem: if your batch really only needed 2 or 3 hours, you’ve just baked it for twice as long as necessary. That means you’re not just wasting energy—you’re actively damaging your resin. Overdrying strips essential moisture that keeps nylon flexible and causes thermal degradation at a molecular level. You won’t see the damage right away, but it’s there, lurking beneath the surface, waiting to show up when your “perfect-looking” parts crack or fail under stress – turning them into a ticking time bomb.

How to Keep Nylon in the Sweet Spot

So, how do you avoid these hidden dangers? While there’s no magic wand, a few best practices can help you stay on track:

1. Store It Smart: Nylon loves moisture, so keep it sealed in moisture-resistant containers whenever it’s not in use.

2. Maintain Your Dryer: Filters, airflow, and temperature consistency matter—check them regularly to keep your system running smoothly.

3. Know the Numbers (or at Least the Risks): That 4 to 6-hour drying range is just a shot in the dark. Every batch is different. And if you’re blindly picking a time, you’re probably overdrying more often than not.

Even with all this, you’re still left guessing. And that’s the scariest part: you can follow the rules and still overdry your nylon.

We’re Here to Help

Here’s the good news: you don’t have to figure this out alone. At Novatec, we’ve been helping processors master nylon drying for decades. Whether it’s nylon 6, nylon 6/6, or blends, we’ve seen it all—and we’re here to help you navigate the challenges.

No sales pitch, no pressure—just a conversation. If you’re dealing with drying issues or have questions about processing nylon perfectly, give us a holler or reach out on the form below. We love talking shop about resin drying and helping processors like you find solutions that work.

Because perfect nylon parts start with perfect drying. Let’s figure it out together.

Ask the Expert: Drying

"*" indicates required fields

Ask the Expert