Self-Contained Loaders Built for Your Process, Your Material Flow

Effortless Conveying. Maximum Uptime. Minimal Hassle.

- Cost-effective, low-maintenance, & specialty loaders.

- Minimize downtime with advanced features.

- We’ve got the right loader for your unique process.

Find the Best Hopper Loader for Your Process

VL Series

XSL Series

GSL Series

Specialty Loaders

Feature

Workhorse Reliability

Enhanced Performance

Best-in-Class

For Niche Applications

![]() Motor

Motor

![]() Blowback

Blowback

![]() Controls

Controls

![]() Flapper

Flapper

![]() Lid Assembly

Lid Assembly

![]() Cleanout

Cleanout

![]() Price (Starting At)

Price (Starting At)

Brushed

External

Simple PLC

Gravity Flapper

Fixed

Fixed

$2,420

Brushed

MicroBurst™

Remote Pendant

SureSeal™

Hinged

Tilted

$3,375

Brushed

MicroBurst™

Remote Pendant

SureSeal™

Hinged

Tilted

$3,665

Powders & Fines

Compressed Air

Auto Blowback

Additive Dosing

Short Runs

Granulator Evac

High-Filtration

Dust Containment

VL Series – The Industry Workhorse

Reliable, Cost-Effective Conveying for Pellets & Regrind

1.5 to 38 lb. (0.7 to 17 kg) Capacity

- Brushed motor delivers strong suction but requires periodic brush replacements.

- External blowback accumulator helps reduce dust buildup between cycles.

- Standard gravity flapper ensures consistent discharge for free-flowing materials.

XSL Series – Smarter Performance with Less Maintenance

A Stronger, More Efficient Upgrade for Higher Uptime

12 to 19 lb. (5.5 to 8.6 kg) Capacity

- All the premium features of the GSL Series, but with a brushed motor.

- MicroBurst™ Blowback & SureSeal™ flapper improves efficiency and discharge reliability.

- Hinged lid & tilt cleanout provide faster, tool-free maintenance access.

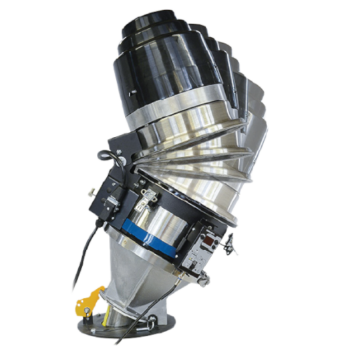

GSL Series – Maximum Uptime, Minimum Maintenance

The Highest Performing Loader, Engineered for Ultra-Low Maintenace

12 and 19 lb. (5.5 to 8.6 kg) Capacity

- Brushless motor eliminates wear & tear – no more brush replacements, ever.

- MicroBurst™ Blowback & SureSeal™ flapper improve efficiency and discharge reliability.

- Tool-free tilt cleanout & hinged lid provide the fastest maintenance access in the industry.

- Handles up to twice the throughput of the VL – higher capacity with less effort.

Specialty Loaders – For Niche Applications

VLP Series – The Powder & Dust Specialist

Reliable Conveying for Powders, PVC, & Ultra-Fine Materials

5 to 38 lb. (2.2 to 17 kg) Capacity

- Engineered specifically for powders & high-fines materials that clog standard loaders.

- Expanded PTFE-coated filters ensure consistent airflow & reduce buildup.

- Automatic blowback system keeps filters clean, minimizing maintenance & downtime.

AL Series – Compressed Air Loader for Low-Volume Needs

Air-Powered Conveying for Additive Feeding & Small-Scale Operations

Transfer Rates up to 500 lb/hr (230 kb/hr)

- Uses a venturi system to create suction – requires only minimal electricity for controls.

- Ideal for low-throughput applications like granulator evacuation & minor ingredient dosing.

- Lightweight, compact design for easy placement in tight spaces.

Novatec Knowledge Centers

Get expert insights and in-depth guides for resin conveying and drying.

Find the Perfect Vacuum Loader for Your Unique Process

- Whether you need a dependable workhorse, a low-maintenance upgrade, or a specialized solution – we’ve got you covered.

- Our experts help you match the best loader to your process – so you get reliable performance without paying for features you don’t need.

- No sales pitch. No pressure. Just a straightforward conversation about what works best for your plant.

Let’s figure it out together!